Both sprocket types use the clutch cover’s hub to transfer energy generated by the chainsaw’s powerhead to produce chain speed and rotate the chain around the guide bar. Their approaches, though, are sufficiently dissimilar to stir some heated disagreement.

The sprocket type that comes with a new chainsaw is usually selected by the manufacturer or, at best, the guy who assembles it at the store. If you are fortunate enough to have a local business that will customize your new saw at the time of purchase, you will have a decision to make.

In this article, we’ll discuss chainsaw rim sprockets vs spur sprockets, so that you can better understand the differences and choose the one which is best for you!

Table of Contents

- Spur Sprocket vs Rim Sprocket: What’s the Difference?

- Rim Sprocket vs Spur Sprocket: Which Is Better?

- Should I Change My Spur Sprocket to a Rim Sprocket Now?

- FAQs (Frequently Asked Questions)

Spur Sprocket vs Rim Sprocket: What’s the Difference?

What Is a Spur sprocket?

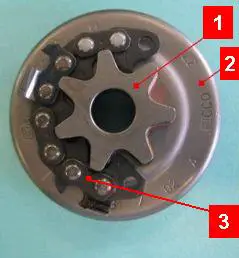

A spur sprocket, also known as a hub sprocket, is a multi-pronged star-shaped sprocket wheel (often with 6 to 8 points) that is integrated into the clutch cover of a chainsaw to make a single monolithic part. This single-spinning element transfers engine power straight from the clutch cover to the chain.

- Oregon 38145X Replacement Pro Spur Sprocket (Bearing 37325 sold separately)

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Spur Sprocket Benefits

- Durability

- Simpler

- Easier chain installation

Greater durability is provided by beefier construction and fewer contact points with the chain drives. There are fewer parts to break or lose. It’s only one basic step. Easier chain installation requires the user to back off the chain tension less while removing and installing a chain.

What Is a Rim Sprocket?

A rim sprocket is a multi-pronged star-shaped gear (often 6–8 points) positioned between two discs to produce a series of channels for the chain to ride in. The rim sprocket is free-floating, riding on the splined hub of the clutch cover. The hub of the clutch cover transfers engine power to the rim sprocket and chain.

- HIGH QUALITY: Made of high quality metal material, sturdy and durable.

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Rim Sprocket Benefits

- Easier to maintain and replace

- Better chain alignment

- Quick customizing

- Lower cost

- More convenient

- Resilient

- Adaptable

Rim sprockets are supported by a clutch cover and a splined hub. They are held on with a washer and an “E” clip and can be readily replaced without removing the clutch cover. This is ideal for making repairs in the woods.

The rim sprocket is free floating on the splined hub of the clutch drum box. This improves the lateral alignment of the chain drivers with the guide bar groove, resulting in less bar wear and derailment.

The inner diameter of a rim sprocket remains constant regardless of its tooth count, pitch, or gauge. This facilitates changing the performance or cutting components of a chainsaw faster and easier. Rim sprockets are less expensive than spur sprockets to purchase.

Because of its tiny size and low cost, it is an ideal complement to any field equipment. Having a spare on hand will allow you to keep your chainsaw running even if you are miles away from town. When a chain breaks, it is less likely to cause damage. The chain will usually slip to the side and not eat up the sprocket teeth.

Rim sprockets can be adjusted to accommodate varied guide bar thicknesses. When utilizing a different guide bar, the worn groove on a spur sprocket may not line up appropriately. This is critical for adjusting bar length for varied cutting requirements or wood types.

Interested in adjusting the bar length? Visit our guides on this matter:

- How to Measure a Chainsaw Bar & Chain Length the RIGHT way

- Are Chainsaw Bars Interchangeable?

- Can I Put a Shorter Bar on My Chainsaw?

- Can I Put a Longer Bar on My Chainsaw?

Rim Sprocket vs Spur Sprocket: Which Is Better?

Choose a rim-style drive sprocket if your chainsaw model enables it. Rim sprockets are superior to spur sprockets because they are easier to maintain, have more flexibility, and are less expensive. Unless you have a very unique use case, you and your chainsaw will be happy with a rim drive sprocket.

Maintenance is key with any component on a chainsaw, visit our Chainsaw Maintenance Checklist & Chainsaw Bar Upkeep and Maintenance guides to learn about all the necessary steps you should be taking!

Should I Change My Spur Sprocket to a Rim Sprocket Now?

A rim sprocket is a good addition. There’s no need to replace a working spur sprocket until it’s worn out. The spur sprocket that came with your saw will last until it wears out. At that point, you should consider replacing it with a rim sprocket, as well as your bar.

FAQs (Frequently Asked Questions)

Which is better rim sprocket or spur sprocket?

If your chainsaw model allows it, use a rim-style drive sprocket. Rim sprockets outperform spur sprockets in terms of ease of maintenance, adaptability, and affordability. Unless you have a very specialized use case, you will be happier with a rim drive sprocket, as will your chainsaw.

Are all chainsaw drive sprockets the same?

Spur sprockets and center drive sprockets are the two types of sprockets used in modern chainsaws. Each of these sprocket kinds has hundreds of variations.

What is different about a chainsaw sprocket?

Rim sprockets can be adjusted to accommodate varied guide bar thicknesses. When utilizing a different guide bar, the worn groove on a spur sprocket may not line up appropriately. This is critical for adjusting bar length for varied cutting requirements or wood types.

When should I replace my spur sprocket?

Both rim and spur drive chainsaw sprockets should be changed when two chains have worn out or if they are broken. Replace the driving sprocket when you replace the guide bar if you use multiple chains every cutting session. It is critical not to use a new chain on a worn-out drive sprocket.